Product Center

Products Introduce

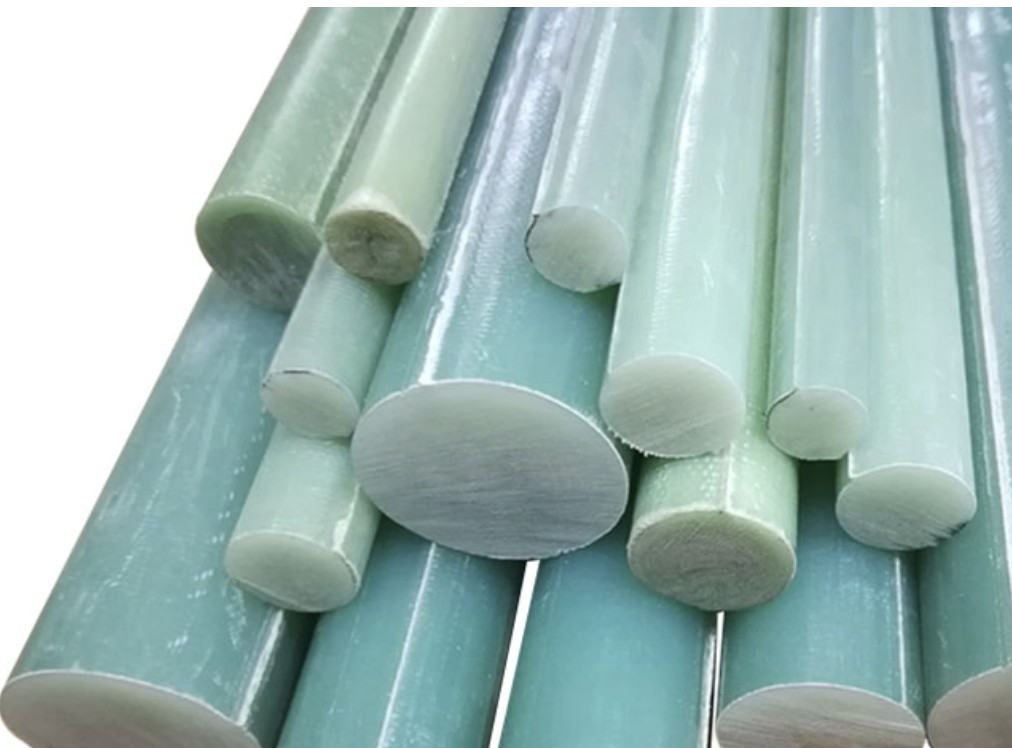

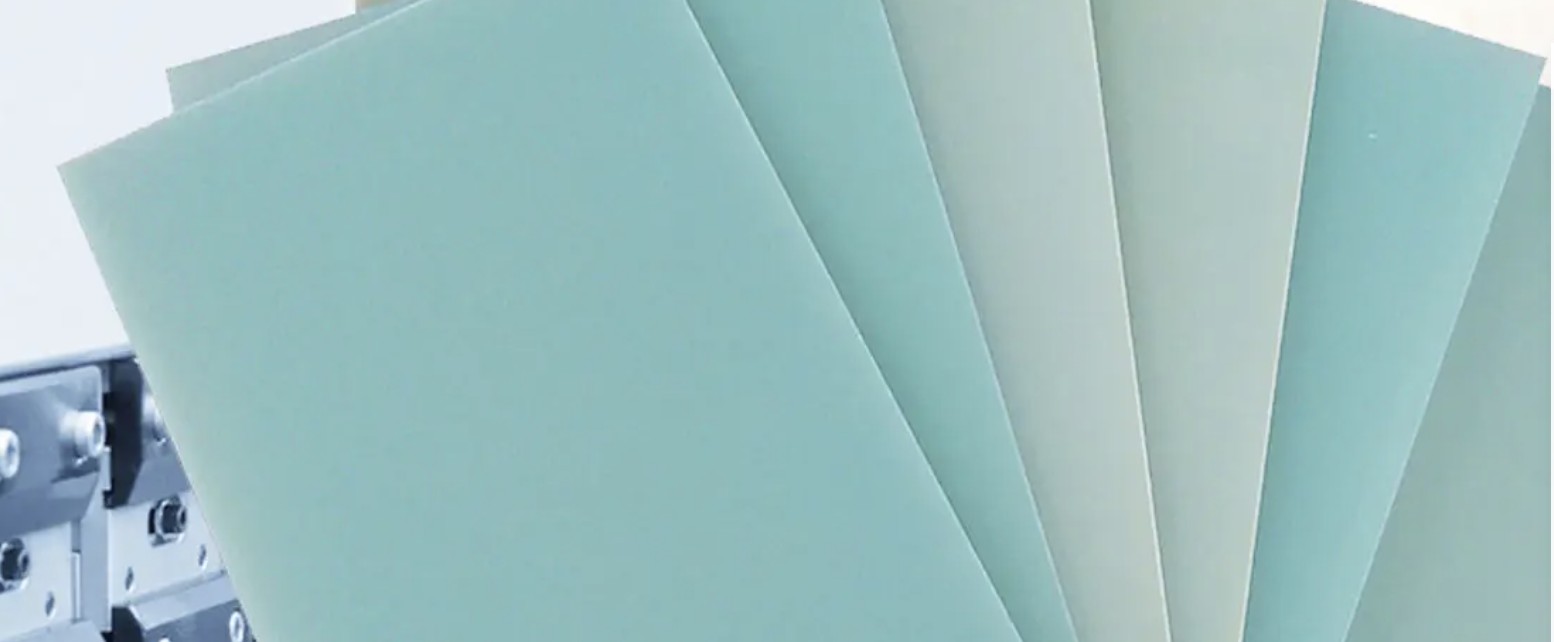

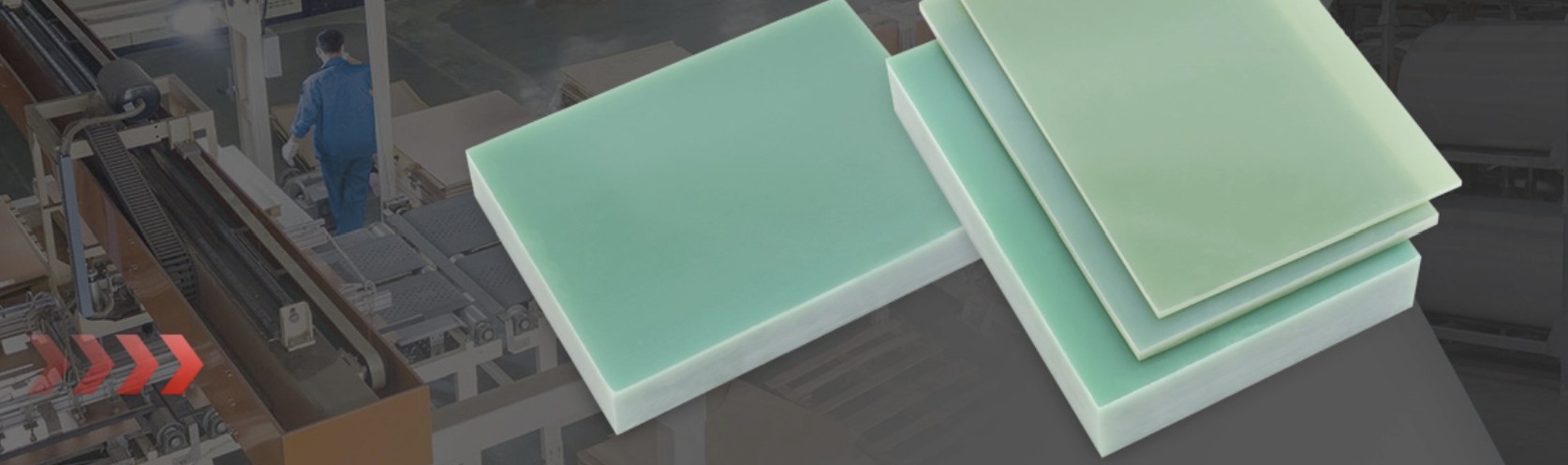

Epoxy Fiberglass Products(Sheets / Tubes / Rods) are composite insulation materials made by laminating, rolling, or pultruding epoxy resin and glass fiber cloth or filaments under high temperature and pressure. Combining the high adhesion of epoxy resin with the high strength of glass fiber, they are widely used in electrical, mechanical, aerospace, and chemical equipment. At RDS Composite, we offer high-performance epoxy fiberglass sheets, tubes, and rods, engineered for demanding industrial and electrical applications. Each product is manufactured using advanced resin impregnation and precision curing techniques to deliver outstanding mechanical strength, dimensional stability, and excellent electrical insulation. Our sheets (e.g. G10, FR4) resist heat, moisture, and corrosive chemicals; our tubes and rods provide robust insulation in high-voltage environments. These composite materials are ideal for transformer insulation, electronic housings, supports, structural components, and more.

Product Advantages

Welcome to RDS --- Trusted Electrical Insulation Composite Material Manufacturer in China

High Mechanical & Electrical Strength

Engineered from premium epoxy resin and fiberglass, our products deliver exceptional tensile and dielectric performance, ensuring stable operation under high load and high-voltage conditions.

Excellent Heat & Chemical Resistance

Withstand continuous exposure to heat, moisture, and corrosive chemicals, maintaining insulation integrity and dimensional accuracy in harsh industrial environments.

Lightweight, Durable & Easy to Machine

Combines metal-like rigidity with low weight, offering superior machinability for custom shaping, drilling, and assembly while ensuring long-term durability and cost efficiency.

Application

Application1

Application2

Application3

OEM Service

Drawing & Requirement Submission

You submit your technical drawings, material specifications and functional requirements; we evaluate feasibility and prepare a customized proposal.

Sample Design & Verification

We design prototypes or small-batch samples for your confirmation, allowing you to test form, dimension and performance before mass production.

Precision Processing & Production

Using CNC, molding or lamination equipment, we manufacture your epoxy fiberglass parts with exact tolerances, quality control, and material integrity.

Quality Inspection & Delivery

Every part is thoroughly inspected (dimensional, electrical & mechanical tests) before packaging and shipment to guarantee compliance with your standards.

Company Advantage

Welcome to RDS --- Trusted Electrical Insulation Composite Material Manufacturer in China

Proven Expertise in Composite Insulation Materials

Over a decade of experience in fiberglass and epoxy composites, providing high-performance insulation products that meet IEC and UL standards for global industrial applications.

Integrated Manufacturing & Custom Solutions

From material lamination to CNC precision machining, we manage every production stage in-house to ensure consistency, customization flexibility, and superior quality control.

Strict Quality Assurance & Certifications

All products undergo comprehensive testing—mechanical, dielectric, and thermal—to guarantee stable performance, with ISO and RoHS certifications ensuring international compliance.

Reliable Global Service & Fast Delivery

Supported by efficient logistics networks, we deliver orders on time worldwide and provide responsive after-sales support for technical guidance and warranty assurance.

FAQs

Related Blogs

The Impact of Mica Sheet Thickness on Application Performance

Mica sheets play a critical role in various industries, from electronics to aerospace. But did you know their thickness can significantly impact performance? Understanding the right thickness for specific applications is key to optimizing their effectiveness. In this article, we’ll explore how mica sheet thickness affects electrical insulation, thermal resistance, and mechanical protection across different industries.

Read MoreThe Broad Temperature Range of Mica

Mica is a remarkable mineral valued across various industries due to its unique properties. Did you know that mica can withstand both extreme heat and freezing cold? This versatility makes it essential in countless applications. In this post, we’ll dive into mica’s broad temperature range, highlighting how it thrives in both high and low-temperature environments. You’ll discover how its exceptional qualities, like heat resistance and electrical insulation, make it an ideal material for critical industrial uses, from electronics to aerospace.

Read MoreHow To Choose The Right Mica Tube Sizes for Your Projects

Mica tubes are essential for electrical insulation, offering high dielectric strength and heat resistance. But did you know that choosing the wrong size can affect your project's performance? In this article, we’ll guide you through the process of choosing the right mica tube size for your needs. We’ll cover how to measure the component accurately, consider temperature and voltage requirements, and select the appropriate material type. We’ll also discuss the importance of thickness, as well as environmental factors like moisture and chemical exposure. By the end of this guide, you’ll be equipped with the knowledge to make informed decisions and ensure the optimal performance of your electrical systems.

Read MoreWhat Is The Difference between Pyrite And Mica

Pyrite and mica are two minerals often found in the Earth's crust, but they are vastly different. While pyrite is often mistaken for gold, mica is known for its unique ability to split into thin, flexible sheets. Understanding the differences between these minerals is crucial for various industries, including electronics and mining. In this post, we’ll explore their composition, appearance, and uses, shedding light on why recognizing their distinctions matters in both practical and historical contexts. You’ll also learn how to identify them in nature.

Read MoreGet Touch With Us

Contact Info

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.

86-18600990778

info@rdscomposite.com