RDS Technology, your reliable partner.

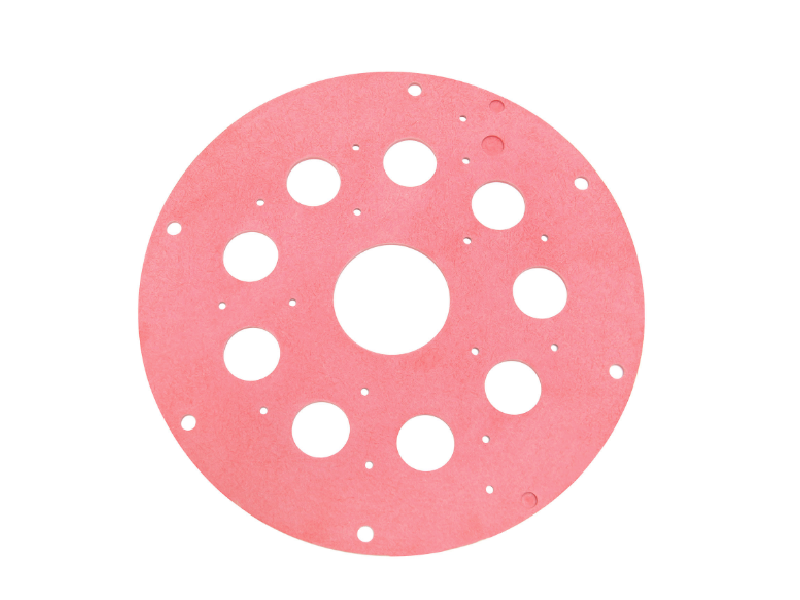

Welcome to RDS, your reliable partner for high-precision CNC machining parts! We specialize in delivering top-quality machined components tailored to meet the unique requirements of various industries. Whether you need intricate mechanical parts, custom fittings, or specialized components for your projects, our advanced CNC machining capabilities ensure precision, reliability, and efficiency.

CNC Machining Parts Series

Products Introduce

Our CNC Machining Parts are crafted using state-of-the-art machinery and cutting-edge technology. We utilize a wide range of materials, including metals and composites, to create parts that are not only strong and durable but also lightweight and efficient. Our team of skilled engineers and technicians ensures that every part is manufactured to the highest standards of quality and precision.

Product Advantages

Achieve unmatched precision, flexibility, and reliability with our ISO 9001-certified CNC machining solutions—customized to meet your exact industrial needs.

Reliable and Versatile Design

Available in various head types and custom sizes, this ISO 9001-certified product ensures high quality, reliability, and stable monthly production of 10,000 pieces to meet diverse industrial needs.

Customization and Flexibility

We offer a high degree of customization to meet your specific requirements. Whether you need a simple modification or a completely unique design, our team can work with you to create the perfect solution.

High Precision and Tight Tolerances

Our CNC machining processes achieve extremely tight tolerances, ensuring that each part is manufactured to exact specifications. This level of precision is crucial for applications where accuracy is paramount.

Application

Application1

Application2

Application3

Customized Whole Process

Communicate Drawing Details

Discuss and clarify drawing specifications with the client to ensure all requirements are understood.

Production Samples

Fabricate samples based on the approved drawings and specifications for customer evaluation.

Send sample and confirm

Dispatch the produced samples to the client for quality inspection and testing. Await client feedback and confirmation that the samples meet their expectations.

Official Production

Initiate full-scale production upon sample approval to fulfill the order requirements.

Contact Us

Boasting a team of seasoned experts, while offering comprehensive one-stop solutions to the global marketplace. If you have any questions or requirements regarding CNC Machining Parts, please feel free to contact our customer service team.

FAQs

Related Blogs

The Impact of Mica Sheet Thickness on Application Performance

Mica sheets play a critical role in various industries, from electronics to aerospace. But did you know their thickness can significantly impact performance? Understanding the right thickness for specific applications is key to optimizing their effectiveness. In this article, we’ll explore how mica sheet thickness affects electrical insulation, thermal resistance, and mechanical protection across different industries.

Read MoreThe Broad Temperature Range of Mica

Mica is a remarkable mineral valued across various industries due to its unique properties. Did you know that mica can withstand both extreme heat and freezing cold? This versatility makes it essential in countless applications. In this post, we’ll dive into mica’s broad temperature range, highlighting how it thrives in both high and low-temperature environments. You’ll discover how its exceptional qualities, like heat resistance and electrical insulation, make it an ideal material for critical industrial uses, from electronics to aerospace.

Read MoreHow To Choose The Right Mica Tube Sizes for Your Projects

Mica tubes are essential for electrical insulation, offering high dielectric strength and heat resistance. But did you know that choosing the wrong size can affect your project's performance? In this article, we’ll guide you through the process of choosing the right mica tube size for your needs. We’ll cover how to measure the component accurately, consider temperature and voltage requirements, and select the appropriate material type. We’ll also discuss the importance of thickness, as well as environmental factors like moisture and chemical exposure. By the end of this guide, you’ll be equipped with the knowledge to make informed decisions and ensure the optimal performance of your electrical systems.

Read MoreWhat Is The Difference between Pyrite And Mica

Pyrite and mica are two minerals often found in the Earth's crust, but they are vastly different. While pyrite is often mistaken for gold, mica is known for its unique ability to split into thin, flexible sheets. Understanding the differences between these minerals is crucial for various industries, including electronics and mining. In this post, we’ll explore their composition, appearance, and uses, shedding light on why recognizing their distinctions matters in both practical and historical contexts. You’ll also learn how to identify them in nature.

Read MoreGet Touch With Us

Contact Info

If you are interested in learning more about our products or exploring collaboration opportunities, please do not hesitate to contact us.

=86-18600990778

info@rdscomposite.com